acrylic-enamel-2k-two-component-glossy-matte-ral-1kg

Color, choose the shade

Finish

acrylic-enamel-2k-two-component-glossy-matte-ral-1kg

Red-orange-yellow / Glossy

Punto Vendita Net Coatings

Via Emilia 2

35043 Monselice PD

Italy

RAL 1035, RAL 1036, RAL 2013, RAL 3032, RAL 3033, RAL 4011, RAL 4012, RAL 5025, RAL 5026, RAL 6035, RAL 6036, RAL 7048, RAL 8029, RAL 9022, RAL 9023, RAL 1026, RAL 2005, RAL 2007, RAL 3024, RAL 3026, RAL 6038

Megasid line enamel ACRILRSID two-component based on acrylic-polyurethane resins recommended for painting high-quality products in general, it offers good adhesion, after pretreatment or sanding, on iron, aluminum and its alloys, galvanized sheet metal, and fiberglass substrates.

Excellent resistance to weathering, good resistance to chemicals, fuels, and fair resistance to solvents.

Available in the following finishes: Glossy, Semi-glossy, Semi-matte, and Matte.

Price per KG, each kit contains Catalyst, thinner sold separately CLICK HERE FOR THE THINNER

Technical data:

Dry Residue (w/w): 58.9 ± 1 %

Viscosity (DIN4/25°C): 75 - 100 sec

Pot life: 6-8 hours at 25°C

Cycle:

can be applied on aluminum and alloys, directly on the substrate if previously pretreated or sanded. To achieve better adhesion on aluminum and galvanized sheet metal and a better anticorrosive effect on iron and its alloys, we recommend the prior application of primer from the Megasid epoxy primer series.

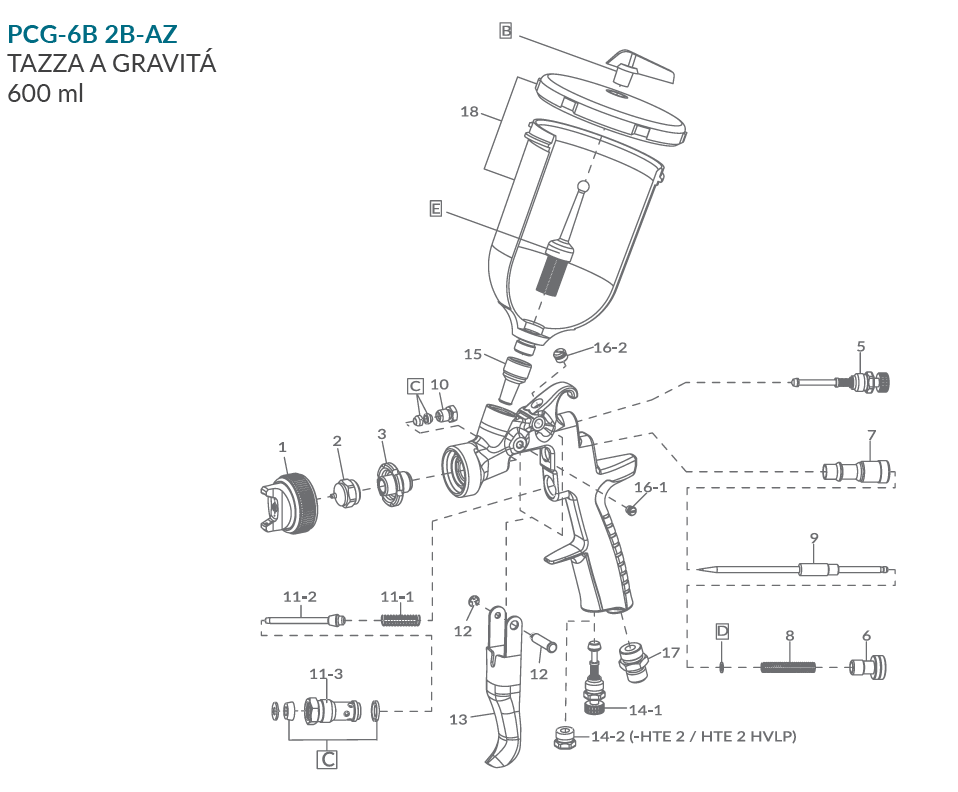

ACRILRSID can be applied not only with traditional spray guns but also with mixed air or airless systems, brush, and roller.

Lower temperatures delay drying, while much higher temperatures can cause surface defects.

The enamels in question must be applied fluidly and in a thin layer, as the high solid content ensures full and glossy films with only two coats.

Insufficient thinning can cause film imperfections (small blisters or craters).

It is advisable that the air drying of ACRILRSID enamels occurs at an air temperature of about 20°C and with not too high humidity.

These enamels are always recoatable, but after more than 12 hours of air drying or accelerated drying in an oven, a light sanding is recommended before recoating.

Theoretical Coverage:

At 30 Microns: 10 sqm ± by spray; for brush and roller, approximately 30% is lost

Thinning:

Up to a maximum of 5% by weight with NC 170 polyurethane thinner

Catalysis:

For Glossy: 50% by weight with catalyst for 34610LM

For Semi-gloss, Semi-matte: 35% by weight with catalyst for 34610LM

For Matte: 30% by weight with catalyst for 34610LM

Incorrect catalysis can irreversibly compromise the color appearance and drying time.

Once catalyzed, do not close the can under any circumstances as the reaction could cause the lid to explode.

Drying:

Dust-free: 20-30 minutes

Touch dry: 3-5 hours

Through dry: 24 hours

Maximum film resistance is achieved after 7-8 days.