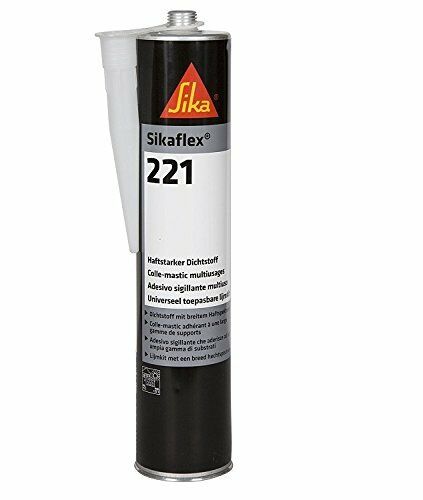

SikaFlex 221 Polyurethane Sealant Adhesive Glue Sika Flex Camper Sealing 600ml

Main color

SikaFlex 221 Polyurethane Sealant Adhesive Glue Sika Flex Camper Sealing 600ml

Black

Punto Vendita Monselice Net Coatings

Via Emilia 2

35043 Monselice PD

Italy

Check the corresponding diisocyanate-free product here (link)

Reach restriction notice 2023:

- Bonds well to a wide variety of substrates

- Aging resistant

- Can be painted

Advantages

-

Bonds well to a wide variety of substrates

-

Aging resistant

-

Can be painted

-

Can be sanded

-

Non-corrosive

-

Low odor emissions

-

NSF approved for incidental food contact

Applications

Sikaflex®-221 bonds well to a wide range of substrates and is suitable for creating permanently elastic seals with high adhesive strength. Suitable substrates include materials such as metals, metal primers and paint systems (two-component systems), ceramic and plastic materials. Consult the manufacturer and carry out tests on the original substrates before using Sikaflex®-221 on materials prone to stress cracking. This product is intended for professional, experienced users only. To ensure adhesion and material compatibility, testing with the substrates under real conditions is necessary.

Also available in 400ml and 300ml packs

Disposal:

Can: FE40 - Ferrous collection

Recycle only if perfectly clean and empty.

Otherwise recycle at designated recycling centers. .

Surfaces must be clean, dry, and free of grease, oil, and dust.

The surface treatment depends on the specific nature of the substrates and is essential for a lasting bond. Tips for surface preparation can be found in the current edition of the appropriate Sika® Pre-treatment Table. It should be noted that these tips are based on experience and must still be verified with tests on original substrates.

Application:

Sikaflex®-221 can be processed between 5 °C and 40 °C, but variations in reactivity and application properties must be considered. The optimal temperature for substrates and sealant is between 15 °C and 25 °C.

Sikaflex®-221 can be processed with manual, pneumatic, or electric piston guns, as well as with pumping equipment. For advice on how to select and set up an appropriate pumping system, contact the System Engineering Department of Sika Industry.

Tooling and finishing:

Tooling and finishing must be carried out within the skin formation time of the sealant. The use of Sika® Tooling Agent N is recommended. Other finishing agents should be tested for suitability and compatibility before use.

Removal:

Uncured Sikaflex®-221 can be removed from tools and equipment with Sika® Remover-208 or another suitable solvent. Once cured, the material can only be removed mechanically. Hands and exposed skin must be washed immediately using hand cleaning wipes such as Sika® Cleaner-350H, or a suitable industrial hand cleaner and water. Do not use solvents on the skin!

Overpainting:

Sikaflex®-221 can be optimally painted after skin formation. Painting may be improved by treating the joint surface with Sika® Aktivator-100 or Sika® Aktivator-205 before the painting process. If the paint requires a baking process (> 80 °C), the best performance is achieved by allowing the sealant to cure completely first. All paints must be tested by conducting preliminary tests under the same production conditions. The elasticity of paints is usually lower than that of sealants. This may lead to paint cracking in the joint area.

Jar: FE40 - Iron Collection

Recycle only if perfectly clean and empty.

Otherwise, recycle at appropriate ecological centers.