Sika Sealant STP Caravan and Camper SikaFlex 522 White resistant to UV and chemical agents

Format

Sika Sealant STP Caravan and Camper SikaFlex 522 White resistant to UV and chemical agents

100ml Bag *WARNING: EXPIRATION 07/30/2025*

Punto Vendita Net Coatings

Via Emilia 2

35043 Monselice PD

Italy

Single-component low-emission silane-terminated polymer (STP) sealant/adhesive.

has high resistance to weather and mold.

Sikaflex®- 522 meets the highest EHS standards.

bonds well to a wide range of substrates with minimal pretreatment.

Adheres well to a wide variety of substrates and is suitable for internal and external elastic sealing and bonding applications.

is suitable for applications in air ventilation areas and accidental contact with food.

Suitable substrate materials include wood, glass, metals, metal primers and paint coatings (two-component systems), ceramic materials, and plastics.

Advantages:

- High resistance to aging and weather agents

- High fungicidal resistance

- Very low emissions and odors

- adheres well to a wide variety of substrates without the need for special pretreatment

- High color stability under UV rays

- Without isocyanates, solvents, phthalates, and silicones

- Meets the hygiene requirements for ventilation and air conditioning systems and units according to VDI 6022, sheet 1 (01/2018)

- ISEGA certificate for use in food areas

- EC1+ Certificate

Application fields:

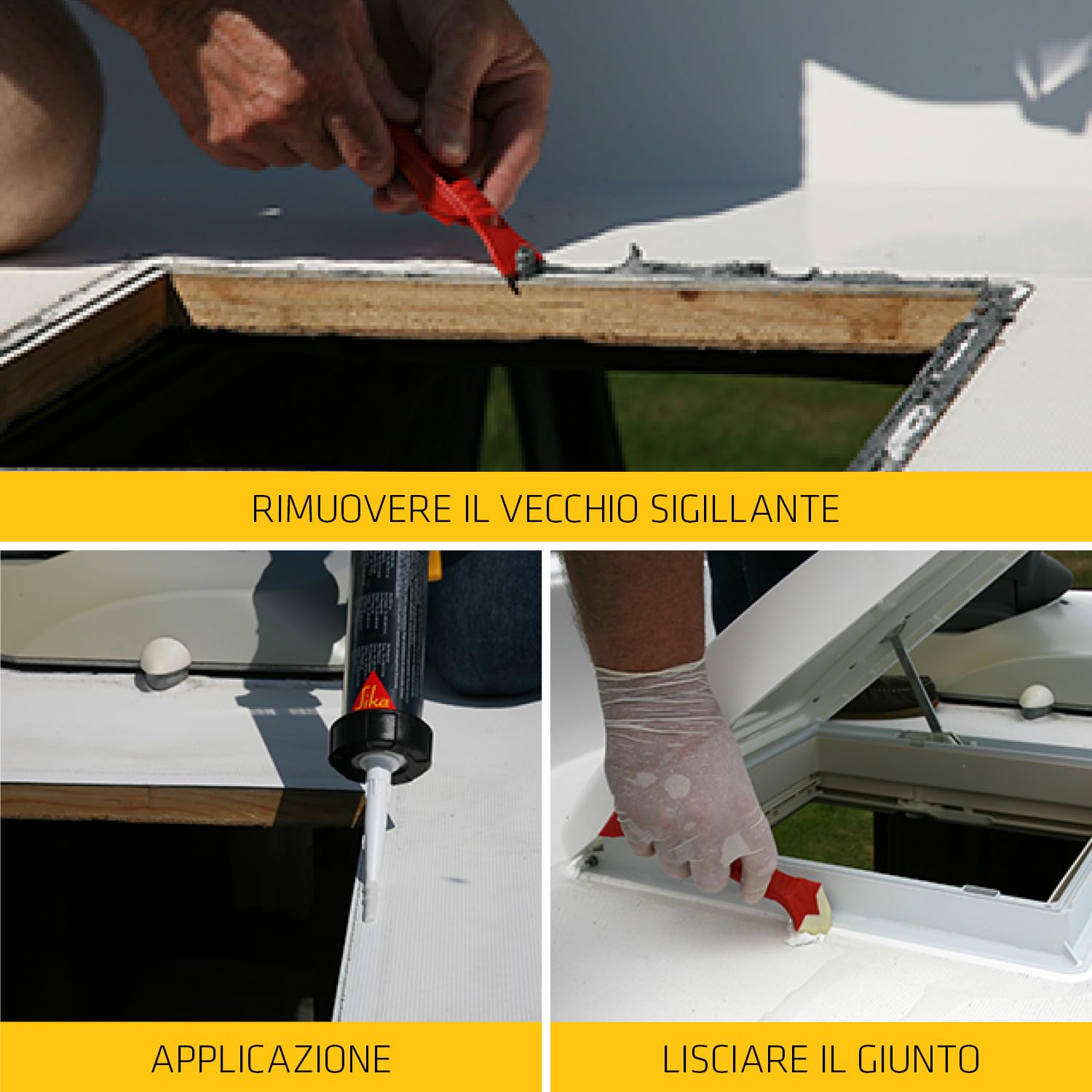

Sikaflex®-522 adheres well to a wide variety of substrates and is suitable for elastic sealing and bonding applications both indoors and outdoors.

is suitable for applications in air ventilation areas and accidental contact with food.

Suitable substrate materials include wood, glass, metals, metal primers and paint coatings (two-component systems), ceramic materials, and plastics.

Ask the manufacturer for advice and perform tests on the original substrates before using Sikaflex®-522 on materials prone to stress cracking.

This product is suitable only for experienced professional users.

Tests must be conducted with real substrates and conditions to ensure adhesion and material compatibility.

Sikaflex®-522 is generally resistant to fresh water, seawater, diluted acids, and diluted caustic solutions; temporarily resistant to fuels, mineral oils, greases, and vegetable and animal oils; not resistant to organic acids, glycol alcohol, concentrated mineral acids, and caustic solutions or solvents.

Overpainting:

Sikaflex®-522 can be best painted within the film formation time.

If the painting process takes place after the sealant has formed a film, adhesion may be improved by treating the joint surface with Sika® Aktivator-100 or Sika® Aktivator-205 before painting.

If the paint requires a baking process (> 80 °C), the best performance is achieved by allowing the sealant to fully cure first.

All paints must be tested by performing preliminary trials under production conditions.

The elasticity of paints is usually lower than that of sealants.

This may cause cracking of the paint in the joint area.

100ML: C/PP 90 - PLASTIC COLLECTION

300ML: HDPE04 - PLASTIC COLLECTION

Check the regulations of your municipality.