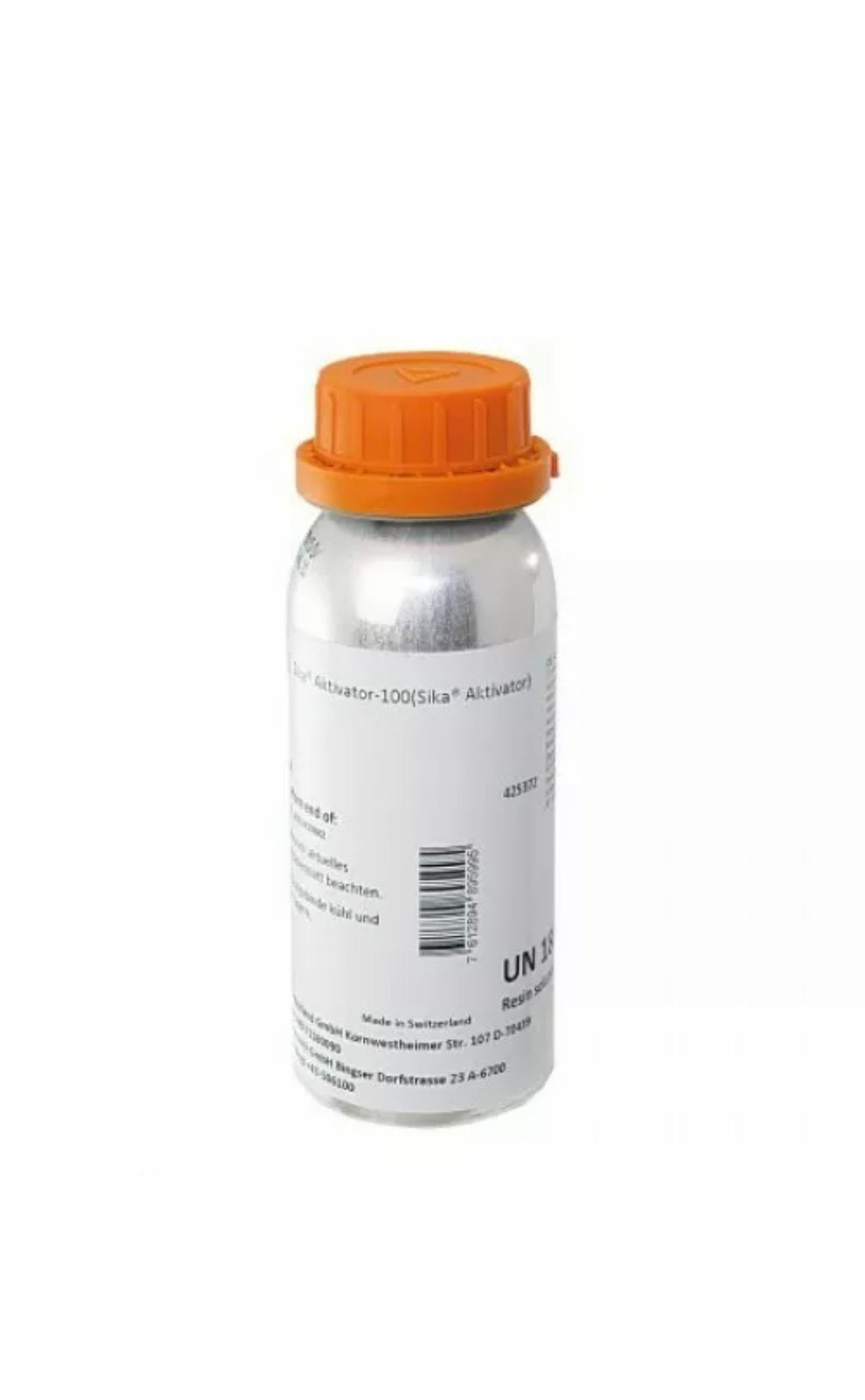

Sika Aktivator 100 Surface cleaner Sealing pretreatment Adhesion promoter

Sika Aktivator 100 Surface cleaner Sealing pretreatment Adhesion promoter

Punto Vendita Monselice Net Coatings

Via Emilia 2

35043 Monselice PD

Italy

Sika® Aktivator-100 is a colorless solvent-based adhesion promoter that reacts with moisture and deposits active groups on the substrate. These groups act as a link between substrates and primers or sealants/adhesives. Sika® Aktivator-100 is specifically formulated for the treatment of bonding surfaces before the application of Sika's elastic adhesives and sealants.

aquatic with long-lasting effects.

Adhesion to substrates can be improved by adding and/or combining pretreatment processes such as abrasion and cleaning before applying the activator.

Clean bonding surfaces with a clean lint-free paper towel dampened (not wet) with Sika® Aktivator-100. Immediately dry with a clean, dry, lint-free paper towel. Never immerse the towel in the activator. Clean the surface only with the clean side of the towel. Never wet the same towel twice and change it frequently.

Sika® Aktivator-100 should be applied sparingly as an excess of activator could cause adhesion failure.

If the pretreated area is not bonded within the maximum flash-off time, the activation process must be repeated (only once).

The ideal application temperature for surfaces is between 15°C and 25°C.

Consumption and application method depend on the specific nature of the substrates.

Seal the container tightly immediately after each use.

Jar: FE40 - Iron Collection

Cap: HDPE2 - Plastic Collection.

Recycle only if perfectly clean and empty.

Otherwise, recycle at designated recycling centers.